Deposition

The Deposition of SilCor® CrN

The manufacturing of chromium nitride coatings at PT&B is performed by means of the so-called "reactive magnetron sputtering“. This technique uses a metallic chromium target (cathode), which is sputtered in an argon-nitrogen gas mixture. Argon ions cause the sputter-ejection of chromium atoms from the target for the growing film. Nitrogen molecules are stimulated within the plasma to react with the growing film. For this reason the term “reactive” sputtering is used.

The ratio of gas flows of argon and nitrogen affects the stoichiometric composition of the coatings and therefore the visual appearance and the macroscopic properties of the chromium nitride. SilCor®CrN shows a silvery shining surface, which is very similar to pure chromium. Quite in contrast, CrN coated by Arc-PVD results in rather dull grey surfaces. Upon request, a customer-defined stoichiometry CrNx coating is available, where the ratio x of nitrogen to chromium is between zero and slightly above unity.

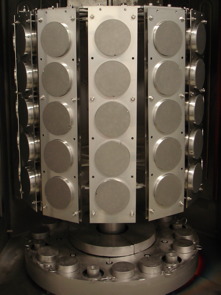

CrN coated steel discs in a STARON 80-100 Sputter-PVD coating apparatus. The holding for single rotation has about the shape a twelve-sided prism.

Small components of nonferrous metal are - for the purpose of allover coating - attached to double rotating circular carriers. On the left hand side the magnetron with chromium target is visible.

A special feature of the PVD-technique used is the directed flow of film forming atoms. Therefore, the allover, uniform coating requires a rotation of the substrates (coating goods). This is a single rotation for plain substrates and a double or triple rotation for three-dimensional substrates. For special purposes as e. g. inner coatings of bores, coating goods keep still in front of the magnetron. This deposition mode is called “stationary”.